The Bessemer process was a key invention which led to Sheffield’s emergence as the ‘Steel City’, but how was it developed, and why?

What is the Bessemer process?

At the dawn of the Industrial Revolution, the demand for iron and steel soared to new heights, driven by the growing needs of construction, transportation, and weaponry. Despite this, the production of steel was still a laborious and costly process, using vast amounts of charcoal, ore and labour. This all changed with the invention of the Bessemer process in 1856 by Sheffield-based inventor, Henry Bessemer. This revolutionary technique changed the way we make steel and, in no uncertain terms, transformed the course of modern civilisation

The Bessemer process is a method for mass-producing steel by blowing air through molten pig iron, removing impurities, and adjusting the carbon content to achieve the desired properties. The process relies on the fact that oxygen from the air reacts with the carbon and other elements in the molten iron, burning them off and leaving a more purified and homogeneous product.

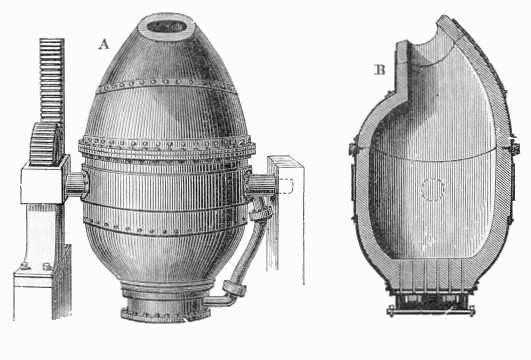

The key innovation of the Bessemer process was the use of a converter, a large vessel made of refractory brick that could withstand the high temperatures and pressures of the process. The converter was tilted at an angle, allowing the molten iron to flow in and out, and connected to a set of blowers that forced air into the molten iron, creating a spectacular flame.

How was the Bessemer process developed?

The development of the Bessemer process began in the mid-19th century, where Bessemer had a conversation with Napoleon III about developing steel for the manufacturing of artillery. In his 1890 autobiography, Bessemer refers to the conversation as:

“the spark which kindled one of the greatest revolutions that the present century had to record, for during my solitary ride in a cab that night from Vincennes to Paris, I made up my mind to try what I could to improve the quality of iron in the manufacture of guns”

At the time steel was only used for small items like cutlery and tools as it was too expensive to mass-produce for cannons and similar applications. By October of 1854 Bessemer had filed his first patent relating to the process, patenting the method in 1856. By forging relationships with various businesses and metallurgists, Bessemer was able to license his method to various different metalworking businesses. His partnership with W & J Galloway, a Manchester based firm, led to the mass production of steel in Sheffield from 1858. The so-called ‘Bessemer Boom’ was another chapter in the city’s illustrious steelmaking reputation.

What were the benefits and drawbacks of the Bessemer process?

Simply put, the Bessemer process was a game-changer for both the steel industry and the world economy. By making steel production faster, cheaper, and more consistent, it enabled a wide range of new applications and industries to emerge, such as skyscrapers, bridges, ships, railways, and weapons. It also created new job opportunities for skilled workers and engineers, and stimulated innovation and competition in the industry.

However, the Bessemer process also had some drawbacks and limitations. One of the main challenges was to control the carbon content of the steel, which could vary widely depending on the quality of the pig iron and the blowing conditions. This led to many failures and defects in the early days of the process, which had to be overcome by trial and error and by using additives such as spiegeleisen and ferromanganese. Another issue was the high cost and scarcity of the raw materials, such as iron ore and coke, which were subject to fluctuations and shortages due to geopolitical and economic factors

The legacy of the Bessemer process is profound and enduring. It not only transformed the steel industry, but also had a ripple effect on many other industries and sectors. For example, the availability of cheap and abundant steel enabled the construction of large-scale infrastructure projects, as well as large-scale production of steel consumer goods, which became affordable and accessible to the masses. Moreover, the Bessemer process paved the way for other technological innovations, such as the development of new alloys, coatings, and composites, which have further expanded the range of applications and properties of steel.

Today, the Bessemer process is mostly obsolete, as newer and more efficient methods of steelmaking have emerged. However, it remains a symbol of human ingenuity and perseverance, and a testament to the power of innovation and entrepreneurship. It also serves as a reminder of the importance of sustainable and responsible manufacturing practices, as the Bessemer process had significant environmental impacts, such as air pollution, waste generation, and resource depletion.

Overall, the Bessemer process was a ground-breaking achievement that revolutionized the steel industry and the world economy. Its impact on history and technology is undeniable, and its lessons and challenges are still relevant today. Just as Bessemer’s innovative spirit took on challenges and developed fantastic new methods of metalworking, at Rotabroach we work to emulate this same attitude; working within the Steel City itself to carry on its historic reputation for quality.